The mighty centrifuge is a staple of labs across the globe, but that wasn't always the case. Its rich history actually started in the dairy industry and even dips into the nuclear arms race. Now, centrifuges come in many different styles, and we can thank a few pioneering inventors for getting the ball rolling.

Let's explore the history of the centrifuge, why the centrifuge was invented and how this instrument has evolved into the vital tool it is today.

Jump To:

When Was the Centrifuge Invented?

That question has a few answers, depending on your definition of “centrifuge.” One of the first versions showed up in the mid-1800s, but a few drastic changes have helped turn it into the equipment we're familiar with.

First Iteration of the Centrifuge

In the 19th century, a brewer named Antonin Prandtl used the concept of centrifugal force to quickly separate cream and milk. Thus, centrifuges were invented in the year 1864, when Prandtl made the first hand-operated centrifuge to help the cream separation process. Around the same time, Friedrich Miescher started to use centrifugation in the lab, where it facilitated his historic discovery of DNA. More specifically, he found nuclein, now known as nucleic acid.

An Upgrade for the Centrifuge

The next big change in centrifuges came from Gustaf de Laval, a Swedish scientist who added continuous rotation to the equipment in 1878. His goals were again related to cream separation, and he made waves in the dairy industry.

At this point, centrifuges were hand-operated and rather slow, reaching just a few thousand revolutions per minute (RPM). Theodor Svedberg changed that in 1924. This colloid chemist invented the first analytical ultracentrifuge, which could create centrifugal force up to 5,000 times the force of gravity.

He later refined his invention to exert hundreds of thousands of times the force of gravity. His landmark invention won him the Nobel Prize in 1926.

Centrifuges in the Medical Field

In the medical field, Edward Pickels added vacuum technology to the ultracentrifuge. Vacuums could help reduce friction due to high speeds while maintaining a constant temperature. Pickels created Spinco — Specialized Instruments Corporation — in 1946 to market his vacuum ultracentrifuge.

It wasn't very successful, but in 1949, he released the Model L. This model was the first preparative ultracentrifuge that could reach 40,000 RPM. Six years later, Beckman Coulter acquired Spinco.

Shop Benchtop Ultracentrifuges Shop Floor Ultracentrifuges

The Centrifuge We Know Today

At this point, the centrifuge started to take shape into the instrument we know today, with improvements like high-speed motors and upgraded blades. Centrifuges even found their way into the Manhattan Project, where physicist Jesse Beams used an ultracentrifuge to separate Uranium-235. Although the Americans ultimately decided to use a different method, the Soviet Union later perfected Beams' tactic.

By the end of the 20th century, centrifuge designs grew to include elements like microliter systems, inverting filters, microprocessor controls and high-performance capabilities.

How Have Centrifuges Changed Over Time?

Since the first centrifuges and Spinco's takeoff, the evolution of the centrifuge has shifted toward ease of use, convenience and safety. Here are some of the ways centrifuges have adapted over the years.

1. Programmability

Early users quickly realized that changing settings with every run was cumbersome and time-consuming. Beckman Coulter's L8 series of centrifuges added memory pacs. These cartridges would store your settings, so you could plug one in, run a program and remove it. Each user had their own memory pac.

Later on, this concept got built into the equipment itself. Beckman Coulter's next lineup, the XL, could support up to nine different programs without the need for cartridges. You didn't need to carry around or potentially lose the extra pieces. Both the memory pac and programmable designs were unique to Beckman Coulter.

2. Cooling Methods

The L8 and XL are also good examples of how refrigeration evolved. The L8 had two compressors. One cooled the drive, and the other cooled the chamber. The XL switched to thermoelectric cooling, which used the Peltier method and only need to cool the chamber floor.

The designers upgraded the drive to negate the need for refrigeration and added a vacuum. Putting the Peltier coolers under a vacuum gives them more than enough power to keep the chambers cold. This new design helped the equipment run quieter, generate less heat and reduce power consumption while providing the same cooling capacity.

3. Motor Designs

In the last few decades, brushed motors have fallen out of fashion. Brushed motors use brushes made of electrodes that provide a pathway for the current to travel to other components of the motor as it spins.

Brushless motors are much more efficient, eliminating the brushes in favor of magnets and coils that don't require any physical contact. They last longer, have minimal maintenance requirements and generate far less noise, heat and dust.

Many centrifuges used brushed motors up until around the mid-2010s. Now, they've been completely phased out.

4. Rotor Styles

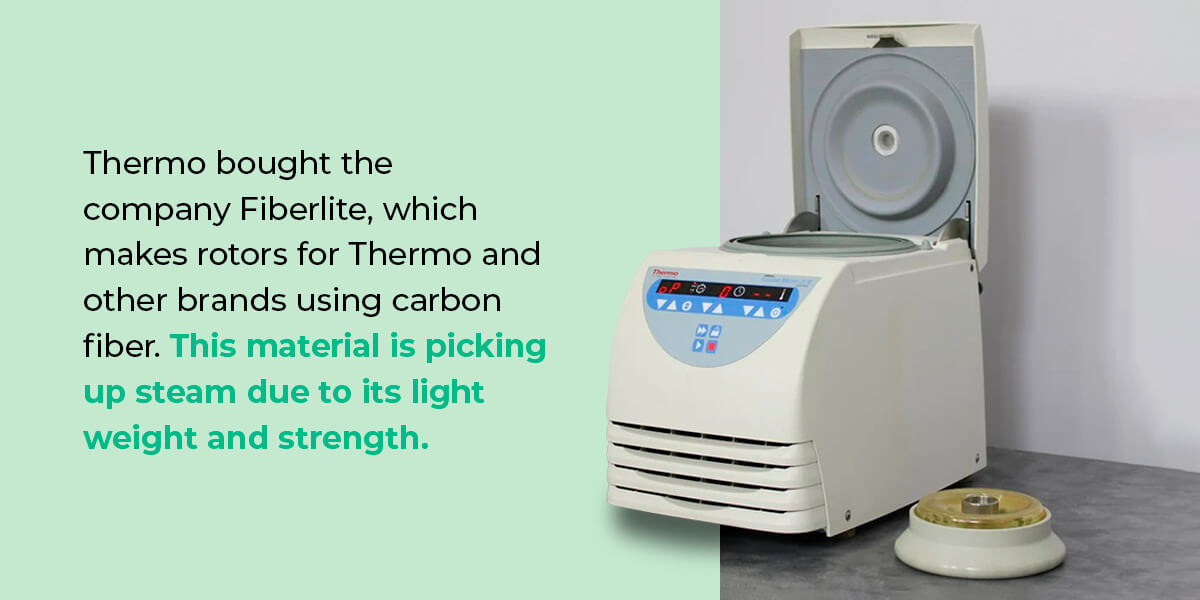

Some manufacturers have updated their approaches to rotor design. Thermo Scientific, for instance, is moving away from rotors that need to be tightened with a screw. Instead, the company has added quick-release buttons that sit on top of the rotor for improved convenience.

Thermo also bought the company Fiberlite, which makes rotors for Thermo and other brands using carbon fiber. This material is picking up steam due to its light weight and strength. It's much safer than other materials, allowing users to move, remove and install the rotors with less risk. Although carbon fiber rotors can be damaged easily, they're an excellent solution for many applications when used carefully.

5. Displays and Buttons

Unsurprisingly, you won't find analog displays on modern centrifuges. Their digital counterparts are usually more accurate and reliable. They also offer a more advanced, modern look. Many models are even adding touchscreens. Only a handful of models from the last 30 years, like the Allegra 6 and the RC-5B+, used analog displays.

Another change to the interface involves swapping rotary switches out for buttons backed by multiplexes and decoders. Surprisingly, Eppendorf has held out on this update. While most other manufacturers have moved to buttons, Eppendorf likely sticks to rotary switches to save space in its small-sized centrifuges.

6. Circuit Board Technology and Internal Components

As with most electronics, centrifuge manufacturers are consistently trying to improve their circuit boards and other internal parts. Most modern changes revolve around phasing out old technology or changing up the programming.

Manufacturers are improving circuit board capabilities and leaning on newer, more advanced sensors, chips and integrated circuits. They can now use fewer boards, for instance, and save space and complexity.

Browse All Centrifuge ModelsThe Future of Centrifuges

While technology continues to advance, we'll most likely see small adjustments with big impacts. Even the old beeps that drive us nuts here in the shop are slowly being replaced by different noises. Thermo, for example, has added the option to play a fun jingle when the centrifuge finishes spinning. It's a small change that makes a noticeable difference.

One area where we haven't seen a lot of change is appearance. Centrifuges are more or less the same colors and sizes as they were 30 years ago. Colors have only seen minor updates, and it often feels like we're ready for a change on these plain hues.

The size restrictions are more understandable, as you can't change the size of a centrifuge's chamber without using smaller rotors. At that point, you're working with a microcentrifuge. Centrifuges also need soundproofing foam between the chamber and the outside walls, so the sizes will stay the same for the foreseeable future.

Choose New Life Scientific for Affordable Centrifuges

Although manufacturers have been steadily refining their products, the basic design of the centrifuge has stayed consistent in the last few decades. At New Life Scientific, we can help you take advantage of that situation with dependable used centrifuges.

Our large catalog of used equipment allows us to offer quick sales and customer support, all at affordable prices. Our team tests everything for quality assurance, and we offer 90-day warranties on all products.

See what we have in stock today, or reach out to us to learn why all types of labs turn to New Life Scientific.

Contact New Life Scientific